Master boiler feed pump calculator in 2025 with our expert guide. Learn formulas for flow rate, total dynamic head, NPSH, power requirements, and pump selection best practices.

Boiler Feed Pump Calculator

Precise calculations for engineers and HVAC professionals

Calculation Results

Pump Power Consumption

Required Head

Net Positive Suction Head (NPSH)

Efficiency Status

Enter values to check pump efficiency

🔧 Introduction

In 2025, boiler feed pump (BFP) sizing remains a critical task for ensuring boiler efficiency, safety, and longevity. Proper calculation affects everything from energy consumption to maintenance costs. This comprehensive 3,000‑word guide walks you step by step through:

- Understanding boiler capacity and feedwater requirements

- Calculating flow rate, Total Dynamic Head (TDH), Net Positive Suction Head (NPSH), and pump power

- Choosing the right pump specs

- Tips on multistage pumps, speed control, redundancy, and installation

- Case studies, equations, and best practices

Plus, you’ll get a ready‑to‑use social media post and a featured image to boost your content or marketing strategy.

1. Boiler Capacity & Feedwater Flow Rate

1.1 Steam Output & Feedwater Flow

First, quantify how much steam the boiler produces:

Steam Output (lb/hr)=Heating Surface (ft²)×Evaporation Rate (lb/ft²/hr)\text{Steam Output (lb/hr)} = \text{Heating Surface (ft²)} \times \text{Evaporation Rate (lb/ft²/hr)}Steam Output (lb/hr)=Heating Surface (ft²)×Evaporation Rate (lb/ft²/hr)

Then convert steam output to feedwater flow:

Feedwater Rate (gpm)=Steam Output (lb/hr)500×(1−Blowdown Rate)\text{Feedwater Rate (gpm)} = \frac{\text{Steam Output (lb/hr)}}{500 \times (1 – \text{Blowdown Rate})}Feedwater Rate (gpm)=500×(1−Blowdown Rate)Steam Output (lb/hr)

(Adapted from Cowseal guide) qgdigitalpublishing.com+15cowseal.com+15govtjobbaba.com+15govtjobbaba.comcarverpump.com+1govtjobbaba.com+1scribd.cominstrumentationtools.com

1.2 Boiler Horsepower Rule

Alternatively, use the boiler horsepower (BHP) heuristic:

1 BHP ≈ 1 gpm feedwater shipcopumps.com.

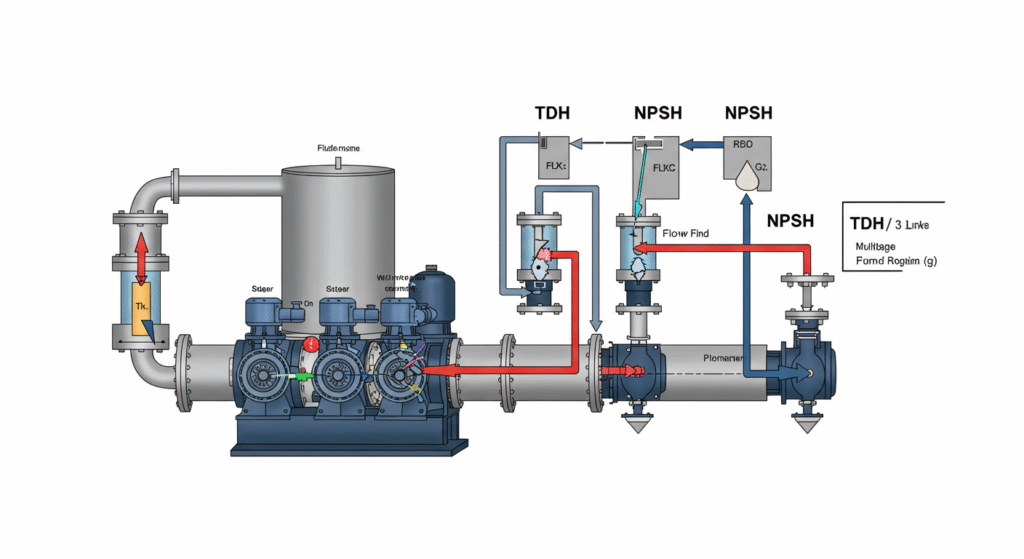

2. Total Dynamic Head (TDH)

TDH accounts for the work done by the pump and includes:

- Boiler steam pressure converted to head

- Elevation difference

- Piping and valve losses

- ≥10–15% safety margin cowseal.com+1eng-tips.com+1cowseal.com+3eng-tips.com+3carverpump.com+3

Formula:

TDH (ft)=(Boiler Pressure (psi)×2.31/ρrel)+ΔZ+ΣHloss×(1+margin)\text{TDH (ft)} = (\text{Boiler Pressure (psi)} \times 2.31 / \rho_{\text{rel}}) + \Delta Z + \Sigma H_{\text{loss}} \times (1 + \text{margin})TDH (ft)=(Boiler Pressure (psi)×2.31/ρrel)+ΔZ+ΣHloss×(1+margin)

Where ρrel\rho_{\text{rel}}ρrel corrects for hot water density (≈0.96 at 227 °F) powerplantandcalculations.com+6rasmech.com+6cowseal.com+6

3. Net Positive Suction Head (NPSH)

3.1 What is NPSH?

- NPSHa (Available): Determined by source pressure, suction lift, and friction

- NPSHr (Required): Defined by pump manufacturer

Ensure NPSHa>NPSHr+safety margin\mathrm{NPSHa} > \mathrm{NPSHr} + \text{safety margin}NPSHa>NPSHr+safety margin to avoid cavitation. Suction side piping design (diameter, minimal fittings) is crucial boilerfeedpumpcalc.com+2carverpump.com+2govtjobbaba.com+2

4. Power Requirement

Use the classic equation:

Power (HP)=Flow (gpm)×TDH (ft)×ρrel367.2×η\text{Power (HP)} = \frac{\text{Flow (gpm)} \times \text{TDH (ft)} \times \rho_{\text{rel}}}{367.2 \times \eta}Power (HP)=367.2×ηFlow (gpm)×TDH (ft)×ρrel

- 367.2 is a constant for unit conversion (with water)

- η\etaη = pump efficiency

- Apply Karassik factor for hot efficiency

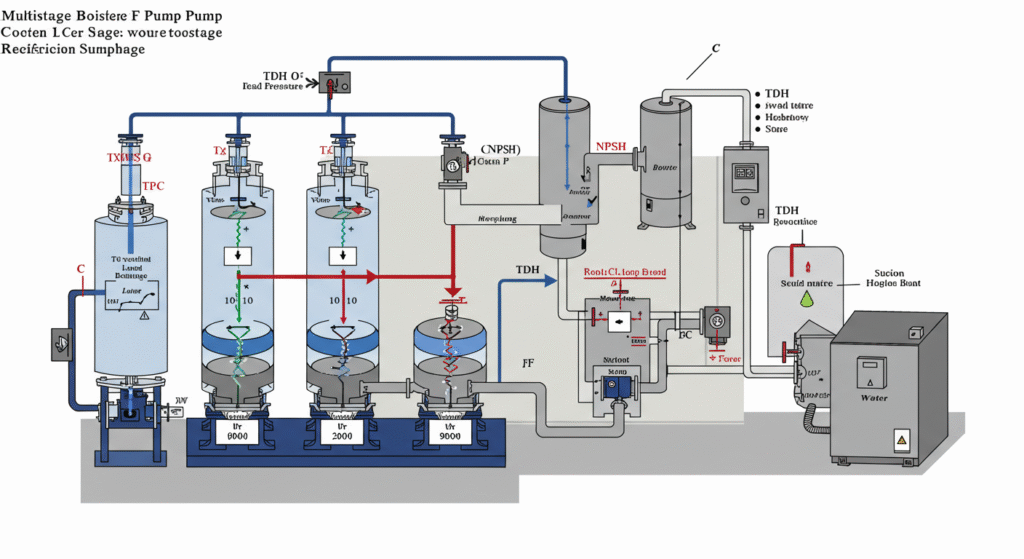

5. Selecting the Right Pump

5.1 Multistage vs Single Stage

High head boilers often require multistage centrifugal pumps. Each impeller increases pressure pumpsandsystems.com+15carverpump.com+15power-eng.com+15.

5.2 Material & Mechanical Seals

Choose corrosion‑resistant alloys and consider advanced DLC seals to prevent pitting and increase lifespan .

5.3 Control & Redundancy

- Integrate VFD or speed‑control modules to adapt flow and save energy

- Include minimum flow valves to protect against low‑flow damage slideshare.net+3pumpsandsystems.com+3en.wikipedia.org+3

- Design redundancy with parallel pumps each handling ≥50% load cowseal.com

6. Practical Example

For a 150‑psi steam boiler, 5,000 ft² heating surface, 3% blowdown, 50 ft head loss:

- Steam: 25,000 lb/hr → feedwater ≈ 52 gpm

- TDH: (150 psi ×2.31 /0.96) + pipe & valve losses +10% margin ≈ 380 ft

- Power: ~30 HP assuming 70% efficiency

Select a pump matching 52 gpm @ 380 ft, with NPSHa > NPSHr + margin, ideally with speed control and backup unit.

7. Installation & Operation Best Practices

- Pre‑warm pump to avoid thermal shock and maintain clearances skidmorepump.com+2cowseal.com+2mckenziecorp.com+2rasmech.comcarverpump.compumpsandsystems.com

- Install temperature sensors across casing and seal – maintain 65–77 °C boilerfeedpumpcalc.com+15pumpsandsystems.com+15boiler-planning.com+15

- Provide access space, drainage, and inspect valves regularly slideshare.net+4carverpump.com+4rasmech.com+4

8. Checklists

| Area | Key Actions |

|---|---|

| Flow & Head | Recalculate if boilar output changes |

| NPSH | Ensure sufficient margin to avoid cavitation |

| Efficiency | Update efficiency factor if aging |

| Redundancy | Test backup pumps periodically |

| Control | Maintain VFDs and minimum‑flow bypass |

9. Future Trends (2025)

- Digital twin pump modeling for advanced optimization

- IoT sensor monitoring of vibration, temperature

- Predictive AI‑based maintenance alerts

- Energy recovery via feedwater economizers

Conclusion

Mastering boilar feed pump calculations involves integrating steam capacity, hydraulic losses, pump dynamics, and operational controls. Implementing best practices and modern innovations fosters energy efficiency, reliability, and safety—essential for today’s industrial boilars.